To make a big difference, Carolina researchers start small — very small.

The biggest breakthroughs come from the right atoms, in the right sequences, building the right structures.

From drug-delivery implants smart enough to read the body to solar cells that turn sunlight into usable energy, the right materials are vehicles for real change. They not only serve the everyday lives of human beings without interruption, they also help protect the Earth instead of wearing it away.

That dynamic work goes on in labs all over the Carolina campus where researchers are using the building blocks of basic science to solve problems in energy, water, health and more by creating new materials or adapting the properties of existing ones for better results. [The scientists and doctoral student featured below are all in the College of Arts and Sciences.]

The most successful materials scientists aren’t working alone, said Nancy Allbritton, professor and chair of the UNC/NCSU Joint Department of Biomedical Engineering. They come from different perspectives and with different motivations, but without partnerships none of them would get very far.

“The greatest inventions and discoveries are at the interfaces of disciplines,” she said. “It’s where you bring these very different disciplines together that things get really exciting and a lot of the true innovative and creative technologies begin to be had.”

Water purification

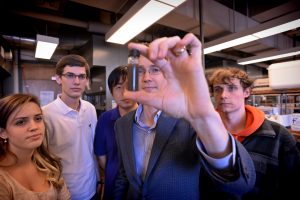

Scott Warren, assistant professor of chemistry and applied physical sciences:

“A few years ago, I was looking at new materials to make solar cells. In that search, I found a particular element, phosphorus, that had a structure almost exactly the same as graphite, like in pencil lead. You can drag the form of phosphorus along a surface and it leaves behind small flakes, very thin sheets.

“It’s an emerging material. The first time scientists proved they’d prepared such thin sheets, it was in 2004, and eventually they won a Nobel Prize in physics for their discovery of thin carbon sheets. Our group is developing just the second example of an element in two-dimensional form.

“We’re thinking of all sorts of applications with this: new kinds of electronic circuits, water purification. We think this material would be effective for absorbing metals and removing them from water as a way to purify it.

“We’re just starting from the basic task of finding this material. We have evidence that we’ve made it. Now, we’ll start exploring these applications.”

A painless vaccine

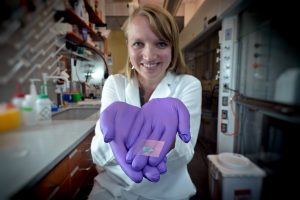

Katie Moga, doctoral student in chemistry:

“A microneedle is a very small projection big enough to break the skin, but short enough that you don’t feel pain. We use arrays of them on a patch so that it looks like a Band-Aid – you put it on your skin and apply pressure to deliver the drug that’s in the projections. It’s like a painless vaccine.

“We design our microneedles specifically with materials compatible with the body. Whatever we load into the microneedles will be filtered safely into the body when the patch dissolves. This is particularly helpful in countries where someone is administering a lot of vaccines at once. If you use something completely dissolvable that goes on the skin, there’s no possibility of spreading infection by accidental needle sticks.

“We are also working on specific applications to deliver chemotherapy via microneedles to fight breast cancer that invades the skin. This method of delivery produces fewer harmful side effects than with IV chemotherapy.

“We work with materials that are already approved by the Food and Drug Administration, which will help this get to market faster when we get to that step. We’ve tried to make this as smooth as possible.”

Accessible solar energy

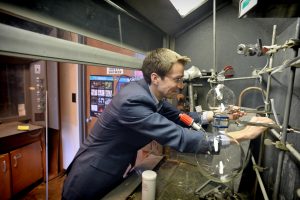

Rene Lopez, associate professor of physics and astronomy:

“For the most part, we know it’s possible to use a solar cell to harness energy, it’s just that it doesn’t impact daily life because it’s not low-cost and efficient enough yet to get it in people’s hands. You can find the solutions, but they are often terribly expensive and impractical, which means they can’t have a wide impact.

“What we’re working on is finding ways to create a material that is cheap, but that also has high performance goals and efficiency. How can we make the existing materials affordable, but perform better?

“The biggest thing I’ve come to recognize is that this stuff is hard. For a material to be well characterized and well controlled, and to know what it’s going to do and have no surprises, it has to be of really high quality. You try to go lower on the quality of the material, and bits of imperfection and impurities will get in, and then give you wildly different behaviors.

“It’s not always easy for students to live with the fact that, if something can go wrong, it will. You have to have creativity and patience to go after all these challenges. You need to work fast to realize what’s not going to work and try to understand what are the key variables to control and understand. You have to move quickly to sort it out because it takes time.

“It’s a good lesson.”

An enhanced body

Nancy Allbritton, professor and chair of the UNC/NCSU Joint Department of Biomedical Engineering:

“We’re building things that have to interface with the human body in the right way. A good example is an implant: if you get a new joint, or some sort of surgically implanted device like a defibrillator or a pacemaker, you need that artificial material to work well with the body. We don’t want a bad reaction.

“The kinds of things we’re looking at for the future are things like flexible devices that are wearable, so a lot of properties have to be associated with that. We have to have the ability to embed the device, it has to be lightweight, and you don’t want it to develop scar tissue or for the body to reject it.

“We have faculty who build particles to release insulin when glucose goes high, and the material that holds the insulin has to be very smart. It has to sense the level of glucose, it has to dump insulin when glucose is high and turn it off when it’s low. That material not only has to perform its job well, but it also can’t make the body upset.

“These are the kinds of things that have become embedded in our lives to the point where we overlook them and might see them as trivial. Most people don’t realize how important these materials are.”

A more sustainable planet

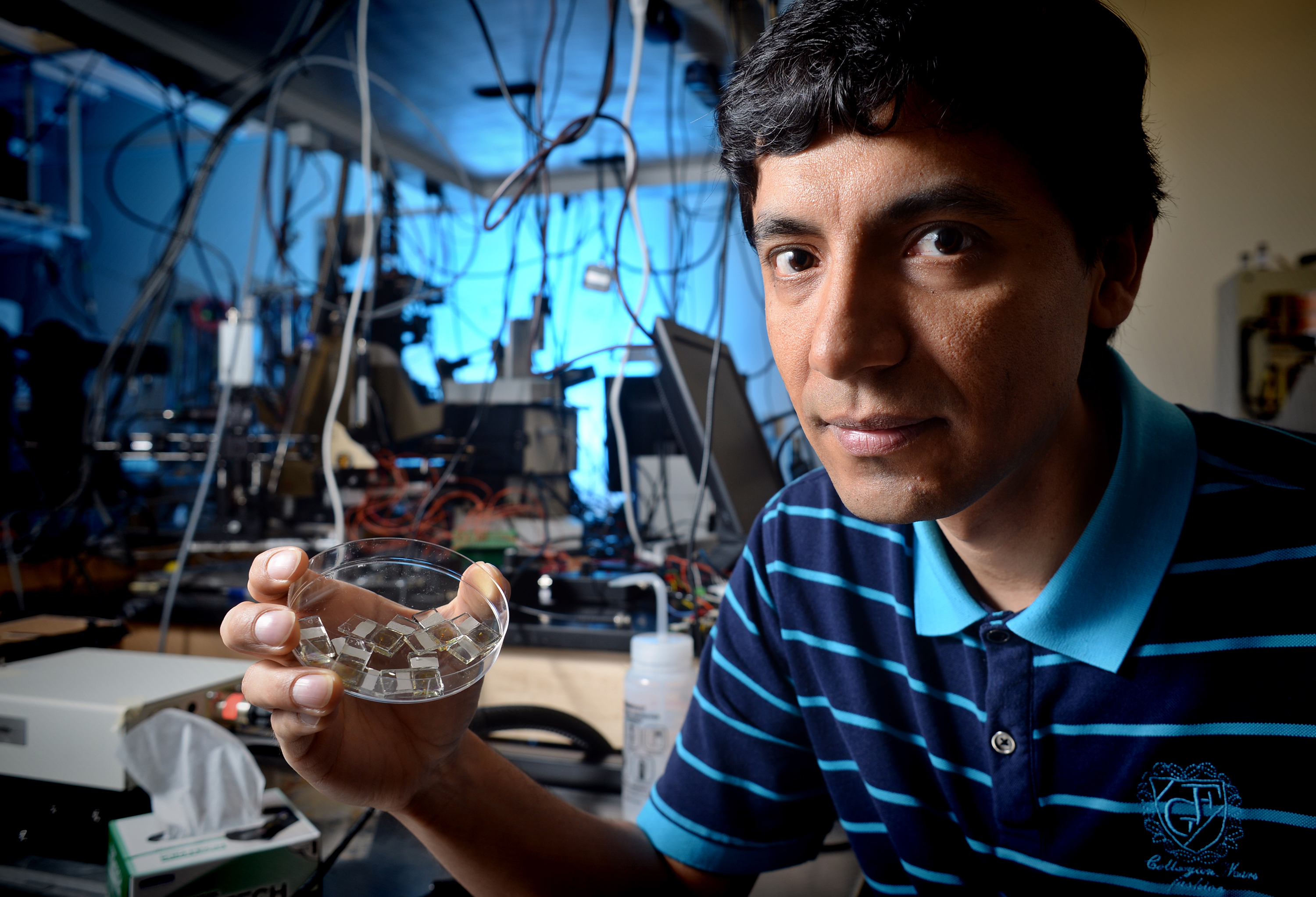

Wei You, associate professor of chemistry:

“As an organic chemist, I am always interested in creating something new. We’re like molecular engineers. We take the atoms, molecular structures, and we put them all together using the chemistry knowledge we have, and we’re constantly creating something new and, hopefully, with desired properties. When we know why a specific structure makes a specific change, we can fine-tune the materials to make them better suit specific applications.

“For example, we’re trying to design materials that will make it possible to convert more sunlight into electricity. The very best you could get would be for 100 percent of the sun’s energy to pass through the material, but that’s not happening. You’re losing some here and there. A higher-efficiency material will convert more sunlight into usable energy, and we’re working on finding those.

“We are hoping that by using solar cells, we can reduce the amount of burning fossil fuels, which creates carbon dioxide and contributes to global warming. Believe it or not, our whole climate system is increasingly messing up: winters don’t feel like winters and summers don’t feel like summers. If we are able to cut back on energy demand from these fossil fuels, we would at least mitigate the problem, and that will buy us more time to solve the climate issue altogether in the end.

“It has been, by and large, an incremental process. But with all these ongoing efforts, it’s is very likely that one day, something just clicks. Whether that’s going to happen to you at year one, year five or year 25, I don’t know – but I know it will happen. And it must happen.”